Case Study

Engineering and Installation of Medium Voltage Drive for Kiln Exhaust ID Fan Cement Plant

Summary

Ingeteam successfully engineered and installed the main drive package composed of: Line phase-shift rectifier transformer + frequency converter + motor, (ELIN make) to drive a kiln exhaust Induced Draft (ID). The project delivery comprised the project management, basic and detailed engineering, single-source responsibility for all components and after sales services.

Top Competences (maximum 6 mentions, out of 15 competences)

Customer Testimonial

"We are very pleased with the final realization of Ingeteam's quality main drive technology and Ingeteam's punctual and budget optimized project delivery."

Project Requirements

In December 2012, Ingeteam received an order from Scheuch, Austria, to supply the main drive package composed of: Line phase-shift rectifier transformer + frequency converter + motor, (ELIN make) to drive the kiln exhaust Induced Draft (ID) fan for INVECEM, Venezuela (former Holcim), in the frame of the expansion phase II of the Puerto Cumarebo Plant aimed at increasing the clinker production up to 4200 t.p.d.

Production of clinker generates exhaust gases that exit from the cold end of a rotary kiln. The solids leaving a cement kiln system in suspension in the exhaust gases are called cement kiln dust (CKD) – typically 30 grams per cubic meter-. By use of a fan (extractor), these particles evolved by the raw materials, are drawn out of the rotary kiln and collected for its treatment. Particles are captured by means of such extractors, which flow is efficiently controlled with a frequency converter which controls the motor and coupled fan.

Technical Features

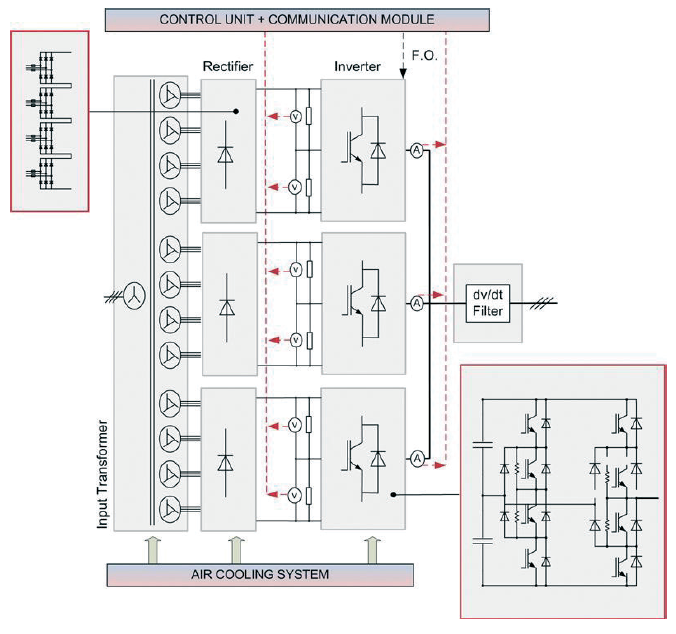

Converter type: Ingedrive MV700

Rectifier: 3x 24 Pulse Diode Front End (3x 24P DFE), non-regenerative

Inverter: Five level voltage source inverter with HV-IGBT power semiconductors, using PWM modulation techniques based on voltage vectors

DC-Bus system: Consisting of high-capacity long-life polypropylene capacitors

Cooling method: Air cooled, with redundant set of fans

Motor: Induction Motor (Squirrel Cage type)

Type: HKL156Z06

Power rating: 2855 kW

Speed: 1180 rpm

Voltage: 6,6 kV

Scope of Supply

- Project management

- Basic and detailed engineering

- Equipment supply: ∙ Ingedrive MV700 converter with integrated phase-shift rectifier transformer

∙ Asynchronous motor (ELIN motoren)

- Commissioning

- After-sales services (360ºCRS)

Erfahren Sie direkt von Ingeteam GmbH mehr zu dieser Referenz:

Besuchen Sie die Webseite von Ingeteam GmbH für weitere Informationen:

Weitere Referenzen von Ingeteam GmbH

|

Engineering and Installation of Medium Voltage Drive for SAG Mill & Ball MillIngeteam successfully engineered and installed the main drive equipment for a 2.3 MW SAG mill and a 2.1 MW ball mill in Russia (Rudnik Alexandrovsky Mine, Zapadnaya Gold Mining Ltd.). The project delivery comprised the project management, basic and detailed engineering, single-source responsibility for all components and after sales services. Referenz öffnen |

|

|

Engineering and Installation of Medium Voltage Drive for New Edger MillIngeteam successfully engineered and installed the medium voltage main drive equipment (rectifier transformer, frequency converter, synchronous motors) for a new edger mill of ThyssenKrupp Stahl. The project delivery comprised the overall project management, single-source responsibility for all components and after sales services. Referenz öffnen |

|