Case Study

Engineering and Installation of Medium Voltage Drive for New Edger Mill

Summary

Ingeteam successfully engineered and installed the medium voltage main drive equipment (rectifier transformer, frequency converter, synchronous motors) for a new edger mill of ThyssenKrupp Stahl. The project delivery comprised the overall project management, single-source responsibility for all components and after sales services.

Top Competences (maximum 6 mentions, out of 15 competences)

Customer Testimonial

"After some initial difficulties we are now very pleased with both the final realization of Ingeteam's quality main drive technology for our new edger and Ingeteam's punctual and budget optimized project delivery."

Project Requirements

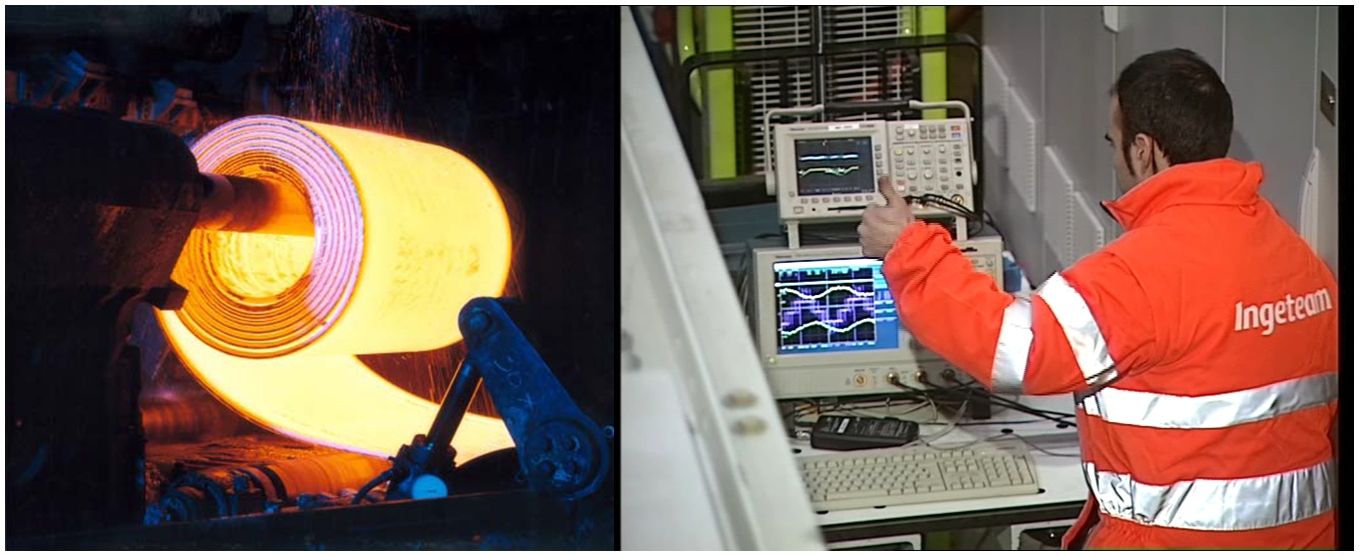

In spring 2007, SMS Siemag AG (formerly known as SMS Demag AG), a leading supplier of plant & mill technologies, commissioned Ingeteam to deliver the medium voltage main drive equipment of the new edger mill to be installed in the ThyssenKrupp Stahl’s existing hot strip mill at its plant in Bochum, Germany, which produces 4.5 million tons per year of hot rolled steel coils.

The order comprised the main drive package including the rectifier transformer, frequency converter (in multi-drive configuration) and synchronous motors. Ingeteam offered single-source responsibility for the main drive package featuring the state-of-the-art technology in INGEDRIVE converters and INDAR motors.

Technical Features

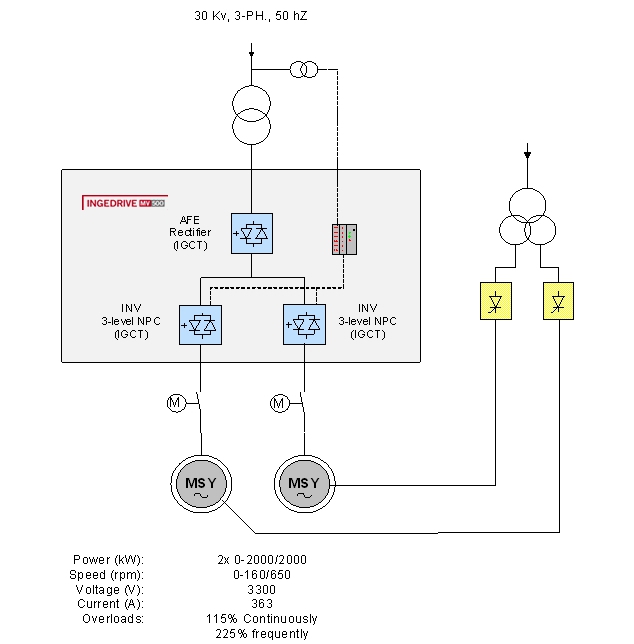

- Converter type: INGEDRIVE MV500

- Rectifier: Fully-regenerative Active Front End (AFE) type, based on IGCT, 3-level NPC topology

- Inverter: (2x) Totally controlled IGCT bridge, 3-level NPC topology, using PWM modulation techniques based on voltage vectors

- DC-Bus system: Consisting of high-capacity long-life polypropylene capacitors

- Cooling method: Water cooled with redundant set of pumps and deionizing unit

- Excitation: 2-Q B6C thyristor bridge for each synchronous motor

- Mill data and features (extract):

* Rolling temperatures 900ºC to 1300ºC

* Automatic Width Control (AWC)

* Progressive Width Control (PWC)

* Short stroke

Scope of Supply

- Project management

- Basic and detailed engineering

- Equipment supply:

* Transformer

* INGEDRIVE MV500 Converter

* INDAR Synchronous Motor

- Combined motor and converter test

- Erection supervision

- Pre-commissioning and commissioning

- After sales services (360ºCRS)

Erfahren Sie direkt von Ingeteam GmbH mehr zu dieser Referenz:

Besuchen Sie die Webseite von Ingeteam GmbH für weitere Informationen:

Weitere Referenzen von Ingeteam GmbH

|

Engineering and Installation of Medium Voltage Drive for SAG Mill & Ball MillIngeteam successfully engineered and installed the main drive equipment for a 2.3 MW SAG mill and a 2.1 MW ball mill in Russia (Rudnik Alexandrovsky Mine, Zapadnaya Gold Mining Ltd.). The project delivery comprised the project management, basic and detailed engineering, single-source responsibility for all components and after sales services. Referenz öffnen |

|

|

|

Engineering and Installation of Medium Voltage Drive for Kiln Exhaust ID Fan Cement PlantIngeteam successfully engineered and installed the main drive package composed of: Line phase-shift rectifier transformer + frequency converter + motor, (ELIN make) to drive a kiln exhaust Induced Draft (ID). The project delivery comprised the project management, basic and detailed engineering, single-source responsibility for all components and after sales services. Referenz öffnen |

|