Case Study

Engineering and Installation of Medium Voltage Drive for SAG Mill & Ball Mill

Summary

Ingeteam successfully engineered and installed the main drive equipment for a 2.3 MW SAG mill and a 2.1 MW ball mill in Russia (Rudnik Alexandrovsky Mine, Zapadnaya Gold Mining Ltd.). The project delivery comprised the project management, basic and detailed engineering, single-source responsibility for all components and after sales services.

Top Competences (maximum 6 mentions, out of 15 competences)

Customer Testimonial

"Zapadnaya Gold Mining Ltd. is really satisfied with the final realization of Ingeteam's quality main drive technology for our 2.3 MW SAG mill and 2.1 MW ball mill. Ingeteam respond to our queries in a fast and efficient manner."

Project Requirements

In September 2011, the company Outotec, located in Espoo (Finland), awarded Ingeteam a contract for the design and supply of the main drive equipment for a 2.3 MW SAG mill and a 2.1 MW ball mill to be installed in Russia. Outotec is a global leading company that designs and delivers turnkey projects in the mining industry, as well as being one of the largest mechanical suppliers of grinding mills worldwide.

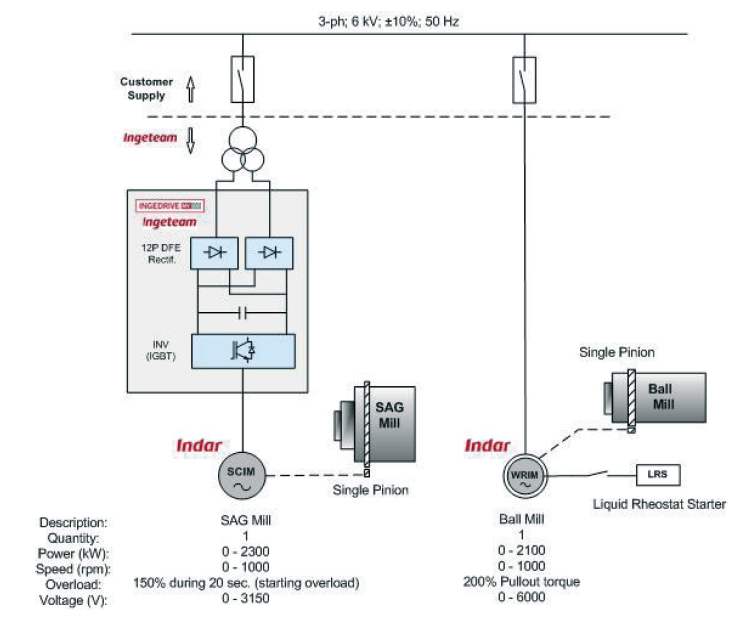

TOMS engineering on behalf of the mine owner awarded Outotec the turnkey project for the grinding mills and process equipment. The end user is setting up a new Greenfield mine in order to produce gold. The order for Ingeteam comprises the supply of medium voltage frequency converter, step down transformer and induction motor for the SAG mill, and Liquid Rheostat Starter (LRS) and slip ring motor for the ball mill. The scope also includes related engineering and on-site services.

In mechanical terms, the torque pulsation and peak torques generated by all types of fixed speed solution during starting ages the mechanical equipment. The benefits of using medium voltage frequency converter in this application will result in a smooth start with low starting currents and low mechanical stresses especially for high power.

Technical Features

Converter type: Ingedrive MV100

Rectifier: 12 Pulse Diode Front End (12P DFE), non-regenerative

Inverter: Totally controlled IGBT, 3-level voltage source, using PWM modulation techniques based on voltage vectors

DC-Bus system: Consisting of high-capacity long-life polypropylene capacitors

Cooling method: Water cooled with redundant set of pumps

SAG mill Functionalities with Ingedrive: - Smooth start

- The drive provides full torque from zero speed

- Optimized starting time

- Inching functionality

- Inspecting mode

- Anti-frozen charge detection

- No liquid rheostat started needed

- Minimized harmonics

Ball mill: Slip ring induction motor was selected for this application given that the application does not require speed variation and due to the LRS starter is the simplest solution for slip ring motor starting

Scope of Supply

- Project management

- Basic and detailed engineering

- Electrical equipment supply: ∙ Phase-shift rectifier transformer

∙ MV Frequency converter (MV100)

∙ 3-ph Asynchronous motor (2300 kW)

∙ Wound-rotor induction motor (2100 kW)

∙ Liquid rheostat starter

- Erection supervision

- Commissioning

- After sales services (360ºCRS)

Remark: Motors are Indar made (an Ingeteam brand)

Erfahren Sie direkt von Ingeteam GmbH mehr zu dieser Referenz:

Besuchen Sie die Webseite von Ingeteam GmbH für weitere Informationen:

Weitere Referenzen von Ingeteam GmbH

|

|

Engineering and Installation of Medium Voltage Drive for Kiln Exhaust ID Fan Cement PlantIngeteam successfully engineered and installed the main drive package composed of: Line phase-shift rectifier transformer + frequency converter + motor, (ELIN make) to drive a kiln exhaust Induced Draft (ID). The project delivery comprised the project management, basic and detailed engineering, single-source responsibility for all components and after sales services. Referenz öffnen |

|

|

Engineering and Installation of Medium Voltage Drive for New Edger MillIngeteam successfully engineered and installed the medium voltage main drive equipment (rectifier transformer, frequency converter, synchronous motors) for a new edger mill of ThyssenKrupp Stahl. The project delivery comprised the overall project management, single-source responsibility for all components and after sales services. Referenz öffnen |

|